Overheads on Production of Plastic Films As A Result Of Blow Film Extrusion Machines

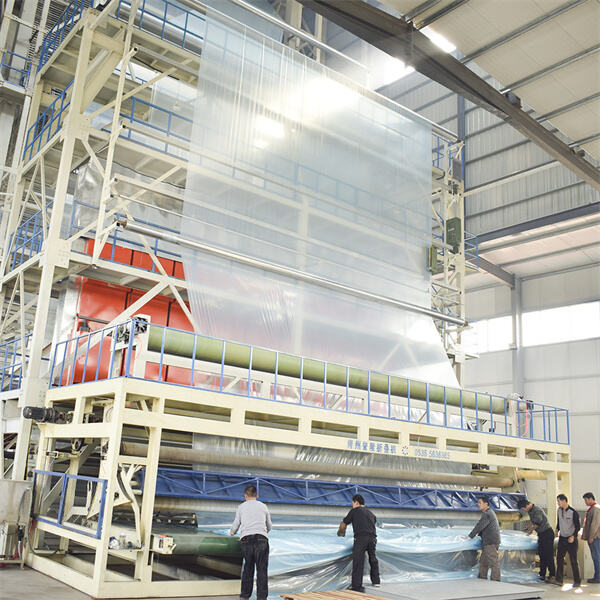

Blow film extrusion is the most widely used technology for producing plastic films, a critical part of packaging and agriculture applications. These complex machines are essential to the process of converting raw plastic resins into thin, continuous films with accuracy and efficiency while still being flexible enough in product handling that it can modify its operation on-the-fly to keep up with market demands. Here, we delve deep into how blow film extrusion technology operates and its associated benefits that include optimising production efficiency, environmentally friendly ways to function,, enhancing barrier properties, an avenue for making a wide variety of products available in the market such as packaging films used within the household as well withstanding competitive standards from top industries.

At the heart of every manufacturing process, lies efficiency and blow film extrusion machines are precisely engineered to produce as much output while generating less waste. These sophisticated systems use real-time monitoring and control technologies such as PLCs (Programmable Logic Controllers) to make adjustments in temperature, speed, flow rates of materials etc. on-the-go for consistent quality film output from the plant gates. Furthermore, rapid changeover die systems allow for quick patterns whether changing to a different film width or thickness thus minimizing machine idle time. They even make the workplace safer by automating such dangerous processes through robotic film handling.

The greatest thing about today's Blow Film Extrusion Machines is the eco-friendly features that you can avail from recent advancements toward manufacturing sustainability. We install new energy-efficient motors and heating systems so that your operation is more efficient without sacrificing any of the production levels. Additionally, the availability of recyclable and biodegradable resin alternatives supports sustainable film manufacturing to align with increasing preference for green packaging solutions. These XINFU blown film extrusion die advanced systems are beneficial in reducing water consumption, and a good friend of the regions that have pressed on with shortages. In addition, certain extruders attract Scrap reclaim and recycling systems that recycle scrap back into the production process which in line with circular economy philosophies to effectively reduce waste.

This is as their customization builds important barrier properties that are required to keep products fresh, maintain shelf life and meet cleanliness standards. Films can be engineered with desired barrier properties by fine-tuning the layer thickness and composition through multilayer extrusion technology. This XINFU blow extrusion machine high level of specialization is especially useful in the food packaging, medical supply and electronics sector when it comes to environmental considerations. These advancements not only improve product quality but can also help reduce food waste and promote patient safety.

This is the kind of innovation that comes out from advancements in blow film extrusion technology and significantly encourages businesses to diversify their product pallets while improving scope for venturing into new markets. This versatility enables these machines to make a wide array of films that vary in density, color and finish from clear shrink wrap all the way to opaque industrial liners. Specialized additives allow companies to give films antimicrobial properties, static dissipation or breathable for agricultural uses. This XINFU abc film blowing machine flexibility allows businesses to quickly adapt in response to the ever-changing market and customer demands, encouraging innovation and keeping their edge against competitors.

With RD Centre blow film extrusion machine 20 years RD expertise, we'll able respond promptly every demand create machines meet customers' particular requirements. work hard provide finest plastic machines every customer.

company currently 2 offices, research center, seven workshops over 100 employees. majority of blow film extrusion machine working in field over decade skilled professionals have vast amount experience. production system totally independent comprehensive, making sure every component equipment purchase manufactured professionals.

will send 1-2 engineers customer's workshop set up, operate operator's training. blow film extrusion machine after-sales support throughout lifetime machine. will keep touch you after during guarantee, provide you assistance.

We blow film extrusion machine reputable film blowing machines manufacturer over 18 years design and manufacturing experience. We mainly produce geomembrane blowing machine, greenhouse film blowing machine, mulching film blowing machine packaging film blowing machines. We served 200+ customers hope offer high-quality product good service you.