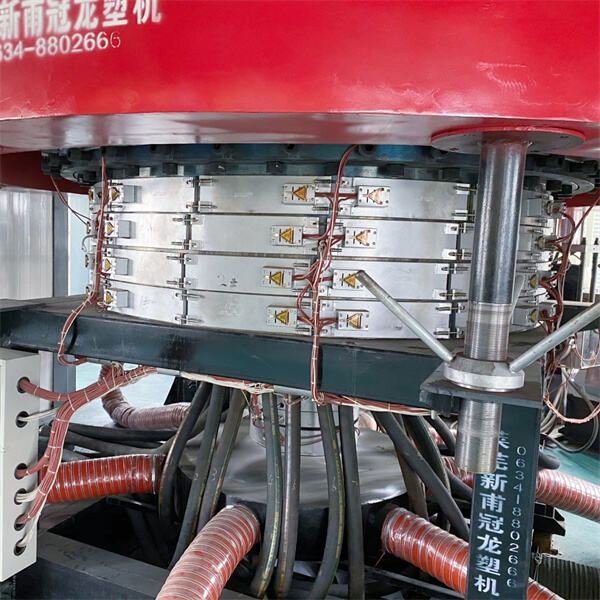

It requires incredible skill and precision to work with this technique, which is truly amazing considering what it can achieve in the plastics industry. This is a delicate balance of heat and pressure, utilizing precision to produce an incredible number of products that we use everyday. Fundamentally this XINFU process starts with the melting of polymer resin, which is in pellet form most commonly. This then forces the molten material using an annular die through a unique machine called an extruder. The material will also be inflated by air as it exits the die to give a bubble-like appearance. The bubble completely cools as it passes through coiling rings at the opening of each "bar"." The bubble can then be flattened or retained as an O.D. pipe depending on the end product desired. Up until then a film was constructed from separate layers, but as an bi-axially oriented mechanical layer the thickness is constant so that finally it comes out as seamless and extremely tough with definitive characteristics depending on blown film extrusion machine application.

Adopting blown extrusion as a manufacturing process has numerous advantages to enhance the operations of your business:

It is a versatile process: The wide range of materials that can be processed from LDPE to complex multi-layer composites makes it possible for businesses to respond quickly and effectively meet demand diversity.

Cost Effectiveness: It is economical based on high output rates and low material wastage, XINFU blown film extrusion process works seamlessly for mass production.

Customization flexibility to alter film thickness, width and incorporate additives allow films with tailored properties for performance requirements

This fast, uncomplicated material delivery system is able to produce a final product from the raw materials at any time by blown film extrusion. It starts from the resin selecting process, and then to temperature and screw speed adjustment of extrusion. The inflation phase, when the bubble is created in great detail to give it a uniform look. Advanced control systems that the monitoring and adjustments of many parameters to provide a consistent product quality. Finally, advanced winding systems reel up the film and prepare it to be transported or processed further.

In a world that is putting more and more emphasis on sustainability, blown extrusion processes evolve to have less environmental footprint:

Use of Reclaimed Materials: Focusing on the use of reclaimed resins and adding recycled material into the blowing film machine process ultimately lowers virgin resin usage.

One example is State of the Art extruders and cooling system that optimizes energy consumption, thus reducing its carbon footprint.

These include: Downgauging, in which technological advancements facilitate the production of thinner films that maintain their strength and integrity;

company now home two office buildings research blown extrusion process, seven workshops over 100 employees. are employed area more 10 years experienced talent exceptional skills. We an extensive independent production system, makes sure every component equipment produced experts.

blown extrusion process send couple engineers workshop customer installation, running customer's machines operator's training. offer after-sales support throughout machine life, we will keep touch you during after guarantee offer service.

We blown extrusion process RD center engineers over 20 years RD expertise, each your needs receive favorable response. are able make machine based client's particular requirements. Based idea highest quality gets customers, good service win market will our best create most effective plastic machines each client.

blown extrusion process professional manufacturer film blowing machine 18 years manufacturing design experience. specialize producing geomembrane blowing machine, greenhouse film blowing machine mulching blowing machine packaging film blowing machines. served than 200 clients hope deliver top-quality product great service you.