A LDPE blown film machines is specifically designed machine which acts a major component in several industries like packaging and agriculture etc as these are responsible for production of plastic films. These are the machines that transform raw LDPE resin into thin resilient films following an intricate path of extrusion, bubble formation and winding. With the development of science and technology, market demand changes constantly, because LDPE blown film machine also further innovation : improve efficiency On energy saving: This is a global issue. Sustainabl...

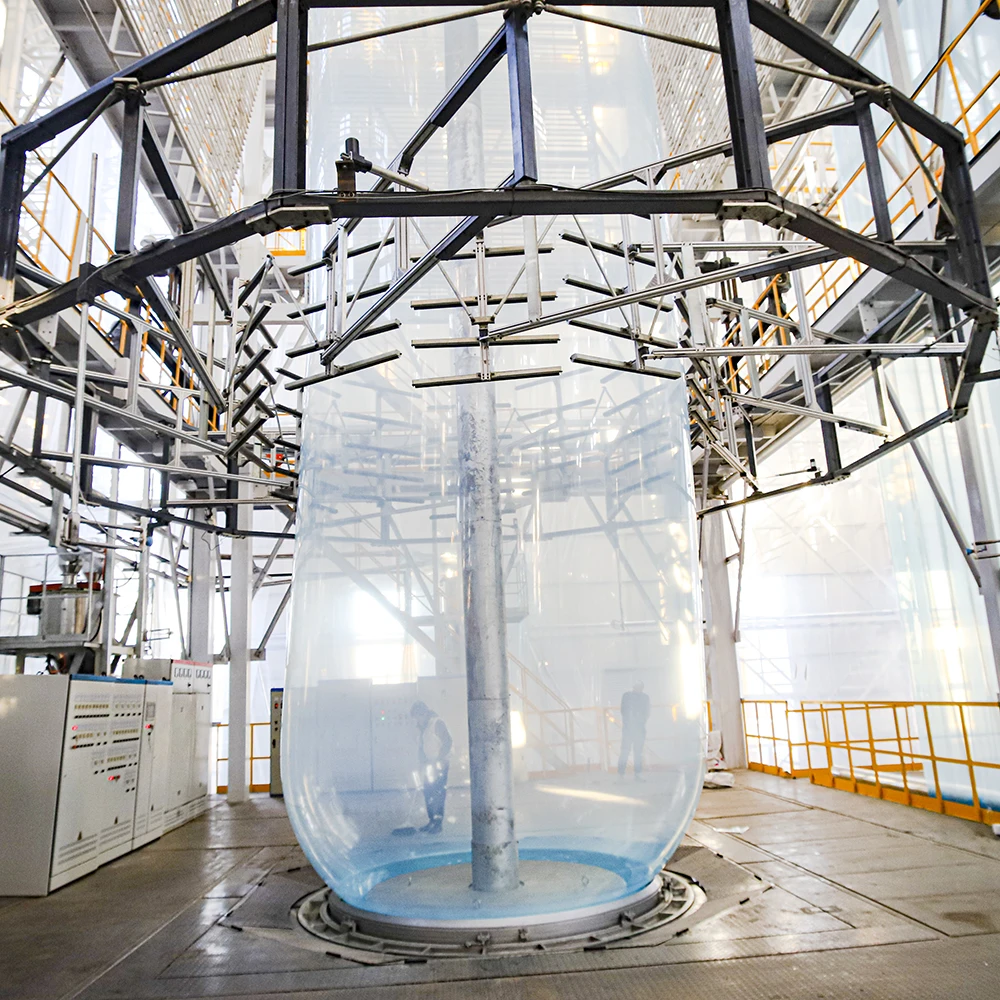

Manufacturers should always strive to be more efficient in their manufacturing processes. This has been possible with the incorporation of modern features in LDPE blown film machines. They use advance control systems like PLCs and HMIs to control temperature, speed, thickness accurately. This way, these machines reduce waste material generation while maintaining quality the same every day. Automatic bubble cooling systems also keep the bio-bubble stable as it is produced at higher rates and more efficient because of energy efficiency. The quick-change die systems also contribute to increased production efficiency by reducing downtime between product changes and maximizing operational uptime.

Sustainability is now more relevant than ever in the plastics industry, and LDPE blown film equipment is following suit. These are innovations mute those environmental consequences of the production process as well they make everything to be recycled. Manufacturers are, therefore creating machinery to handle and extrude biodegradable or recycled resins that become eco-friendly packaging. Efficient motors and heating systems keep energy usage to a minimum, as well as exhausts that make for light emissions. Thin-film technologies allow thinner films to be produced whilst still maximising strength which in turn reduces the plastic required per pack protecting and supports a view of moving towards circular economy ambitions.

Manufacturer of plastic goods - in the truly competitive market for suppliers, almost every second is pure gold... or wasted profit. Equipped with the latest LDPE blown film lines and able to run at speeds in excess of 400 meters a minute, delivered increases volume through-put (with no proportional increase in labour or energy costs). This results in faster manufacturing cycles and decreased cost of each unit of film produced. High-speed LDPE blown film machines deliver consistent quality, maximizing the ability of manufacturers to meet demand for orders as well enable them in discovering new markets and/or approaching suppliers/customers more assertively which can add some value with a strong bottom line.

It is featured with the integration of new technologies in LDPE blown film machinery. A major development was the multi-layer co-extrusion process, which enables to manufacture highly structural films for customizing according to applications leading up-to barrier film in food packaging. Infrared and ultraviolet curing systems are methods to combine prints with the film that improve properties such as printability or durability. In addition, the integration of Industry 4.0 technologies such as IoT sensors and data analytics allows real-time monitoring for machine health (condition-based maintenance) as well as predictive maintenance to reduce unplanned downtime while increasing overall equipment effectiveness. Not only do these advancements increase the quality of our products, but they also future proof how we make them.

With RD Center engineers more 20 years RD experience, respond positively each demand ldpe blown film machine machines meet clients' specific needs. work hard supply most efficient plastic machines possible each customer.

ldpe blown film machine now 2 offices, research center, 7 workshops, over 100 employees employed business. majority our staff been working industry more10 years highly skilled specialists years knowledge. production process independent complete, ensuring every component equipment you purchase made experts.

will ldpe blown film machine couple engineers the workshop customer make sure installation operation machine purchased customer training operators. offer after-sales support throughout machine life, we be contact you throughout after guarantee, provide you assistance.

We' re professional manufacturer film blowing machine 18+ years design manufacture experience. design manufacture ldpe blown film machine mulching, packaging greenhouse film blowing equipment. have served more 200 clients hoping provide quality product good service you