One of the production equipment for packaging materials is a mini type blown film machine. They are very popular these days because of how good and efficient they can make films. They are known to be user-friendly, trustworthy, and durable which is why they have a good demand in the industry.

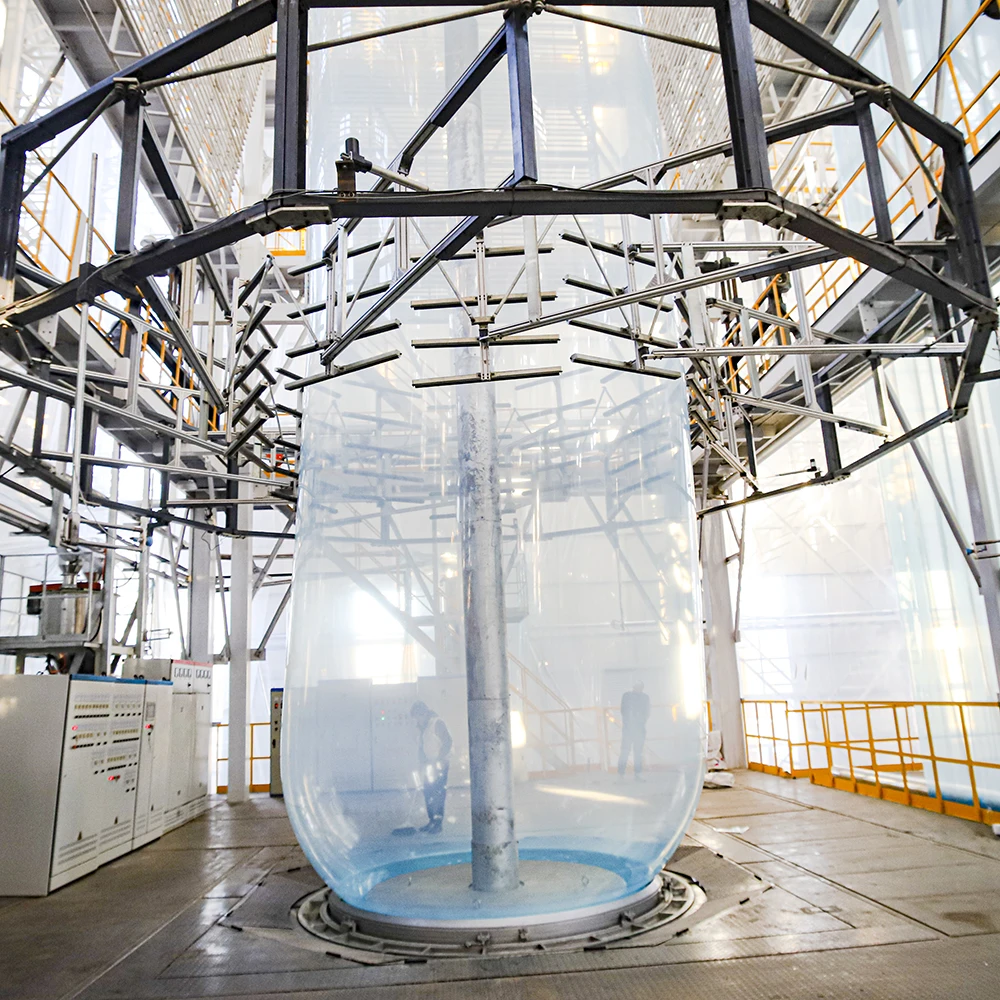

They also follow a very complex process in order to function, so let's break down how these machines actually work. The machine melts plastic material and then forms the film flat via sheep series of technical equipment. In this process key components like the blowing unit and die head have crucial role to play. Moreover, the machine features an automatic loading system f1-3ded202506 which also has a film thickness control and intelligence in software to process various kinds of packaging films.

Manufacturers and suppliers of packaging materials that adopt a mini type blown film machine can revolutionize their production lines. The machines bring forth a host of advantages that can improve efficiency, cost-effectiveness and productivity. Some of their main benefits are that they can make different films like LDPE, LLDPE, HDPE and PP films with the same machine. What saves even more money (especially considering that equipment malfunctions and repairs are rarer) but it also simplifies the type of manufacturing process this company can offer to its customers.

In addition, energy-efficient mini type blown film machines that require little maintenance. More importantly, this feature lowers operating costs as well so that businesses can choose these in a cost-effective manner. This user-friendly design along with the safety mechanisms will improve productivity and reduce accidents at work.

There are several important factors to consider when a mini type blown film machine is chosen. The rate in which the machine can produce (production output) is limited by the quantity of film that enters and exits this space over a unit period. The bottom line is, you can scale up a little and must look for machines based on your average parts/production rate. It is also important to determine whether the equipment you will use at your production site can efficiently operate in conjunction with a machine of this size.

Secondly, the word of film you want to produce also affects on machine selection. There are varieties of machines for elders used to make a specific kind of film, and you may select the one that suits your requirements. While these factors need to be taken into consideration, it is possible yet to find a mini type blown film machine that costs less but offers decent quality of service. This is because respected manufacturers provide top grade machinery at very competitive rates, enabling businesses to have access to advanced technology without going over their budgets.

Overall, the mini blown film machines offer an innovative and solution that had been missing among manufacturers or producers in packaging line. Using those machines along with keeping the below point in mind during selection, businesses can not only achieve better efficiency and cost savings but increases their productivity too. The decision to select a suitable model as per the requirement and capacity of business will help businesses take advantage from these mini type blown film machines in full.

now 2 office mini type blown film machine, one research center, 7 workshops, over 100 employees our organization. majority staff been field over 10 years highly skilled professionals a wealth experience. We a fully independent production system, makes sure every component equipment produced professionals.

We a top manufacturer film blowing machines over mini type blown film machine years experience design manufacturing. mainly produce geomembrane blowing machine, greenhouse film blowing machine, mulching film blowing machine packaging film blowing machine. have provided 200 customers anticipate providing with quality products top-quality service.

a RD Centre engineers more 20 years RD mini type blown film machine respond positively each request design machines meet clients' particular requirements. do everything can provide best plastic equipment each customer.

mini type blown film machine arrange 1-2 engineers visit customer's workshop guarantee installation, operation machine purchased customer as well operator's education. provide after-sales service along lifespan machine. will in contact you during after guarantee offer assistance.