An In-Depth Monolayer Blown Film Machine Guide

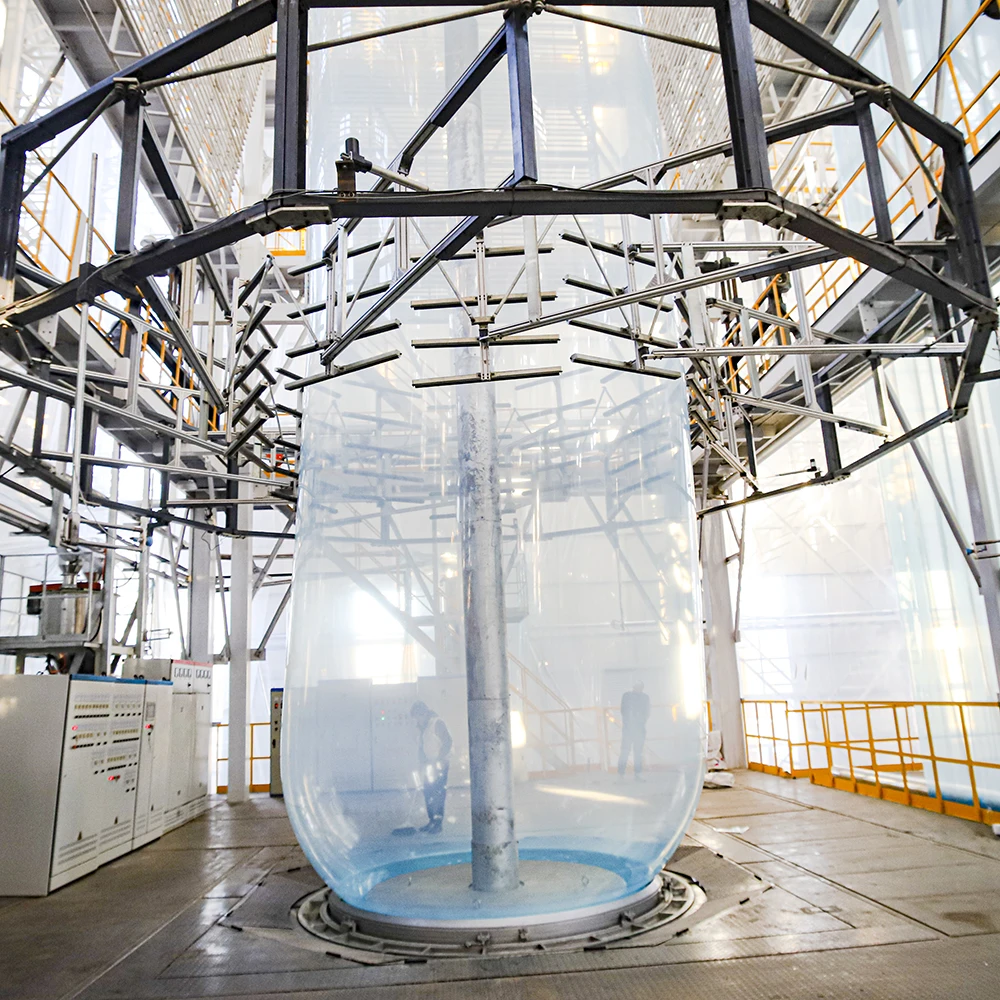

Monolayer blown film machines are essential to the production of packaging material for a large number of products such as food, beverages or other consumer goods. Powered by sophisticated technology, these machines produce thin film of clear plastic resin through melting and extruding the resins.

Plastic pellets are fed into the extruder of a monolayer blown film machine, which melt in this section before being forced out through an apparatus called as die head. In this case, the melted plastic is formed into a tube using such a die head; from here it gets expanded and stretched to desired thickness/widht. Incredibly, these machines can produce films in all dimensions up to 1-10 microns and into the range of millimeters.

Top 5 Monolayer Blown Film Machines of 2021 - A Closer Look

Kuhne Group is a reliable manufacturer of monolayer blown film machines that provide an extensive range from entry-level to high-speed models. The Kuhne Group machines are famous for having the best quality and reliability in comparison to other machines used by industrial professionals.

WINDMÖLLER & HÖLSCHER

Another key player in the market, Windmöller & Hölscher — is engaged in providing monolayer blown film machines which are used for food packaging, garbage bags and agricultural films. Their machines are known for energy-saving, high efficiency and being very user-friendly.

Reifenhäuser, Germany is known to supply all-rounder monolayer blown film lines that offer high versatility with sustainability and quality. These machines can produce films of thickness ranging from 15 microns to up to 250micron, thus catering by the demands of different industries.

Bandera based in Italy, the well-known provider of long-lasting and high performing monolayer blown film machines. Offering very large working widths of up to 3,000 millimeters.Downward CoatingThese machines are popular for industrial applications.

DOLCI (Italy): Dolci, the Italy-based company is among one of the prominent manufacturers of monolayer film blowing plants which are primarily used for various sectors like food packaging, medical industry as well as industrial packages Their technology is highly appreciated because of their high efficiency, easy to use options and low maintenance cost.

Increased productivity through the Monolayer Blown Film Machines

To maximize efficiency out of monolayer blown film machines, choosing the right machine for a given application is key. Film thickness, width and output capacity are all part of this selection process. In addition, by choosing a machine that is primarily easy to use and energy-efficient this will increase performance all round.

It is also important that the machine be maintained regularly and used correctly to achieve maximum efficiency. Such can include keeping it clean, and replacing the parts when they are due to for replacements as well as setting processing parameters like temperature, pressure & speed just right.

The Technology of Monolayer Blown Film Machines

A monolayer blown film machine is employed by means of application heat, pressure, and stretching to produce top-notch films. The film was made by melting plastic pellets in the extruder and drawing them into a cylindrical tube using die head, then blowing to leave finally thickness/widt it drop based on further blow-stretching.

In particular, difference between the extension part and mechanical behavior of film such as strength and elasticity in transparency. Manufacturers influence the properties of such films by guiding how far and in what direction they are stretched so that PLA-based multilayer films can show different characteristics depending on design requirements.

Importance of Monolayer Blown Film Machines Developed with Packaging Production

Its use is important for the leading role of monolayer blown film machines in packaging production, and how they enable more efficient and cost-effective: flexible films. They are used in a range of industries, from food packaging to industrial and medical applications.

Monolayer blown film machine allows for stronger, thin and translucent films that have some inherent advantages over other packaging materials. These properties are very versatile so that, these can be tailored to suit a specific need by adding such property as tear resistance, oxygen permeability or UV protection which fits both food and beverage sector through pharmaceuticals to cosmetics.

So, Yesterday I covered how pivotal monolayer film extrusion is in the world of flexible packaging materials. By carefully identifying the proper machine, optimized operating to efficiently enable operations streamlining and lessen costs units will truly make a film specially designed to their requirements. By optimizing the use of these machines, businesses can benefit from an adaptable and cost-effective packaging solution suitable for a wide range of needs.

currently two monolayer blown film machine buildings, 1 research center, 7 workshops over 100 employees employed our business. Most them working area more ten years, possessing seasoned talent exceptional capabilities. We a fully independent production system, which sure every component equipment made professionals.

We an RD monolayer blown film machine engineers over 20 years RD experience. Each request positive responses we a machine based client's special requirements. In spirit management, highest quality customers, great service key winning customers we'll everything create most effective plastic equipment every customer.

monolayer blown film machine arrange 1-2 engineers visit customer's workshop guarantee installation, operation machine purchased customer as well operator's education. provide after-sales service along lifespan machine. will in contact you during after guarantee offer assistance.

We' re monolayer blown film machine manufacturer film blowing machine more 18 years design manufacture experience. mostly manufacture geomembrane blasting machine greenhouse film blowing machines mulching blowing machine packaging film blowing machine. We've more 200 clients anticipate providing highest quality products exceptional service.