Now in a world of constantly changing tech, industries are faced with many challenges and opportunities to scale. This revolution is carried out to the manufacturing sector as well, where companies are already following newer practices (or adoptions of previous technologies like IoT devices and data management software) making their operations cost-effective that eventually generate revenue in such a saturated market. This is truly a money making solution and the amusement machine being by virtue of muliblow film plant, whether it be bags or sachets and even pouches.

The process is very versatile and the films produced on these machines are in a wide range of thicknesses for many types packaging materials. This leads to making products that are not just more powerful, yet likewise a lot much more long-lasting so they can maintain the things held within them safe. It extrudes and bonds a multi-layered plastic film to create packaging material that is high quality and weather resistant. So it is an affordable option for the protection of perishable food as well sensitive medical devices.

Modern Day Customer ChoicesOur fast moving consumer market requires customers to not only deliver packaging that is functional & visually appealing but also sustainable as well. An excellent example are multilayer blown film machines that make an easier life for manufacturers to produce aesthetically and environmentally friendly designs. These machines with this high tech mechanization deals really well with intricate packaging design and sometimes which compliments a product package brand to make it relevant, becomes an important leverage in your promotion.

The Leading Packaging Industry --Multilayer Blown Film Machinery

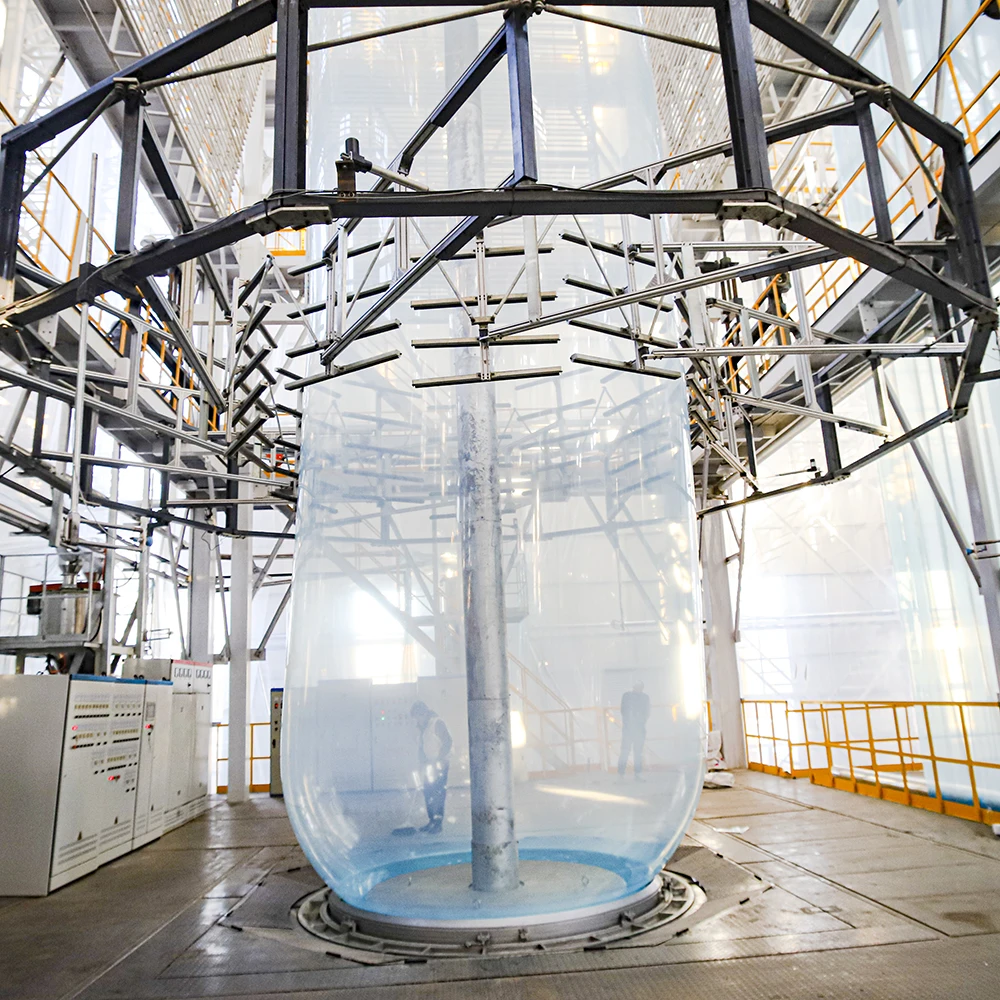

The popularity of multi-layered films also reflects well on the demand for multilayer blown film machinery, as a wide acceptance in packaging applications shifts with enhanced functional alonger with visual properties achieved by these films. The adoption of the form-fill-seal machine has reduced legacy stand-up single-layer packing. In the case of multilayer blown film machines more than one material is added to make it a type and mix, giving as an example films with characteristics such that humidity/gas barrier (nylons series), tensile strength / elongation (polyethelines) or even packaging designed in nylons + polyproylenes. The choice of packaging materials leads to a greater rigor and, therefore, improves the quality all in favor ofproduct protection or shelf life.

One of the key advantages offered by Multilayer blown film machines is to bring consequential improvement in eliminating waste whilst production. These are technology-intensive machines and this incorporation of the same on these MACHINE allows micro-meter control over thickness resulting into minimum waste for raw material consumption to achieve desired quality. These machines also combine with reclaimed plastics reducing of disposable plastic on the environment and as a result perform more broadly fulfills some purposes than merely degrades them into their simplest form - recycling. Machines configuration can be optimized single or multiple extruder for each material type getting more production in one machine location, reducing process machines number and also contributing to the resource efficiency of environmental performance.

The manufacturing process also means less material can be used, which makes sworn blown films a greener alternative to single-layer film packaging with more substantial waste. Value-add these machines deliver to any packing company ranks higher as they enhance quality of packed product, and reduce wastage by utilising its species elements which are getting included in customer searches for eye catching & environment friendly packaging products. With the large growth in technology and more availability of these machines, it can only be expected that additional new features to enhance multi-layer blown film machinery will continue to make it an even greater part for packaging.

We multilayer blown film machine RD center engineers over 20 years RD expertise, each your needs receive favorable response. are able make machine based client's particular requirements. Based idea highest quality gets customers, good service win market will our best create most effective plastic machines each client.

We a top manufacturer film blowing machines over multilayer blown film machine years experience design manufacturing. mainly produce geomembrane blowing machine, greenhouse film blowing machine, mulching film blowing machine packaging film blowing machine. have provided 200 customers anticipate providing with quality products top-quality service.

will multilayer blown film machine couple engineers the workshop customer make sure installation operation machine purchased customer training operators. offer after-sales support throughout machine life, we be contact you throughout after guarantee, provide you assistance.

company multilayer blown film machine offices research centre, seven workshops over 100 employees. Many employed field more 10 years, possessing seasoned talent amazing abilities. have comprehensive independent production system assures each part equipment designed experts.