Machines d'extrusion de film : Les machines utilisées dans la production de films quotidiens. Vous vous êtes peut-être déjà demandé comment l'emballage plastique qui maintient vos aliments frais, celui qui protège votre siège de voiture d'une tache de café pendant que vous roulez sur l'autoroute, et des millions d'autres petits miracles conçus pour nous protéger et rendre notre vie plus confortable sont produits ? La réponse est une merveilleuse petite chose appelée machine d'extrusion de film. Cette machine est véritablement un équipement ingénieux de production de film qui fabrique des films utilisés dans une multitude d'outils de notre quotidien. Pensez à en apprendre davantage sur les machines d'extrusion de film et découvrez comment ces dispositifs fonctionnent et pourquoi ils sont précieux. Ce que fait une machine d'extrusion de film pour les utilisateurs. Lorsqu'on travaille avec une machine d'extrusion de film, les utilisateurs peuvent créer des films de différentes largeurs et épaisseurs, produisant un produit conforme aux attentes des clients qui le demandent. Les utilisateurs peuvent créer des films de leur choix sans avoir à utiliser ou se conformer à des tailles et épaisseurs standardisées, ce qui économise les dépenses des clients. Machines d'extrusion de film en continu ou en ligne. Cet avantage réside dans le fait que l'appareil peut produire des films pour divers secteurs, tels que l'emballage alimentaire, l'automobile, la construction et la santé, grâce à la nature flexible des industries diverses qui utilisent des films. Cela est possible car une seule machine peut être adaptée aux besoins d'une variété d'entreprises, ce qui est un atout pour les entreprises de différents secteurs. — assurez-vous qu'il n'y ait aucune inquiétude concernant le départ du rail. Ce produit soulève une autre préoccupation sensible. Toutes les mesures de sécurité relatives à l'utilisation des machines doivent être prises en compte. De plus, lorsqu'elles sont utilisées correctement et complètement, ces machines peuvent potentiellement être dangereuses. Comme les personnes qui exploiteront ces systèmes doivent savoir comment elles fonctionnent et les gérer, il est important qu'elles soient informées sur le fonctionnement des machines et toujours averties sur leur utilisation ainsi que les entretiens réguliers. De plus, il incombe au fabricant de réaliser un contrôle annuel de maintenance de toutes les machines. Cela peut être effectué par une personne qualifiée spécialisée dans l'entretien et la maintenance des machines.

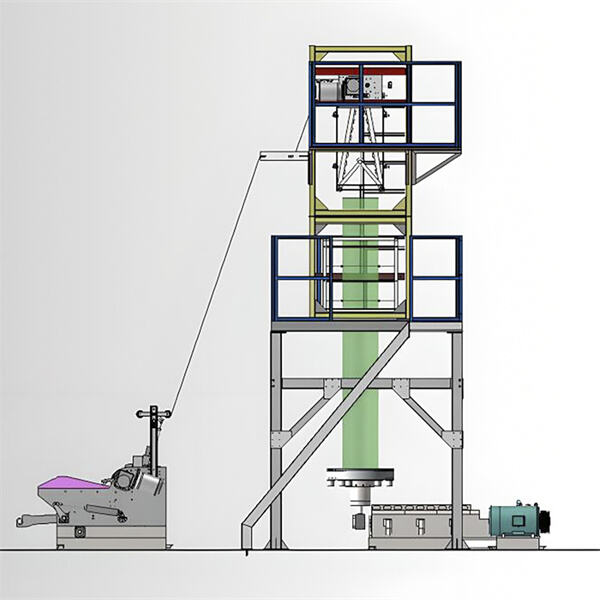

Vous pouvez continuer à utiliser cette méthode tant qu'elle est évidente et facile à expliquer à quiconque les étapes de base de l'opération des machines d'extrusion de film. La machine est ensuite chargée avec le matériau brut qui, encore une fois, est fondu et forcé à travers une forme pour obtenir sa forme finale. Une fois fabriqué (ci-dessus à gauche), le film est refroidi et positionné sur une bobine pour sécher, puis soit emballé, soit stocké avant d'être traité par des installations guidées par un opérateur surveillant des spécifications strictes.

L'apparence produite changera certainement en fonction du type et de la qualité de l'installation utilisée. En général, les ventes des fabricants de machines d'extrusion de film peuvent offrir une gamme complète, y compris les services après-vente tels que l'installation et l'entretien. Le choix des services d'un tel fournisseur établi et bien connu garantit qu'une machine fonctionnera efficacement.

Les machines d'extrusion de film pour les films d'emballage comme les poches, les BiBs et les sacs debout, etc. De plus, les emballages thermoformés ainsi que certaines pièces de l'industrie automobile sont également produits en utilisant des extrusions de film.marker Les extrudeuses de film sont également utilisées dans l'industrie médicale pour produire des produits tels que : - Tubulures médicales - Poches à sang - Poches IV.

Comprendre l'importance des machines d'extrusion de film pour différentes industries, une technologie largement utilisée qui affecte notre vie quotidienne de bien des manières.

Très polyvalentes par nature, ces machines peuvent produire des films destinés à être utilisés dans diverses industries, y compris l'emballage alimentaire, l'automobile, la construction et la santé. Cette flexibilité permet à une seule machine de répondre aux besoins de plusieurs secteurs et offre de nombreux avantages aux fabricants dans différentes branches.

Lorsqu'il s'agit d'utiliser tout type de machinerie, la sécurité est le facteur le plus important, et cela s'applique également à une machine d'extrusion de film. Suivez les instructions de sécurité pour éviter tout accident ou blessure. Pour que les machines fonctionnent comme prévu, les employés doivent être correctement formés sur la manière dont ils sont censés utiliser et entretenir une machine, ainsi que des inspections régulières de l'équipement effectuées par les fabricants ou du personnel qualifié.

Tant que vous suivez un processus simple avec des étapes normales, n'importe qui peut faire fonctionner une machine d'extrusion de film. La matière première est chargée dans la machine et fondue à nouveau, après quoi elle passe par une filière afin de prendre sa forme finale. Ensuite, le film est refroidi et positionné sur une bobine pour être soit stocké, soit traité, mais toujours sous l'œil vigilant de l'opérateur qui surveille pour s'assurer que les spécifications sont respectées.

Les films produits varieront certainement en fonction du type et de la qualité de l'installation utilisée. En règle générale, les fournisseurs de machines d'extrusion de film offrent des services complets après-vente, tels que l'installation et l'entretien. Choisir un fournisseur expérimenté et réputé garantit la qualité, la performance et le fonctionnement de la machine.

l'entreprise possède maintenant 2 bureaux ainsi qu'un centre de recherche, des ateliers de machines d'extrusion de film avec plus de 100 employés. Ils travaillent dans l'industrie depuis plus de dix ans, avec une grande expérience et une expertise remarquable. Le système de production est totalement indépendant et complet, ce qui signifie que chaque composant de l'équipement n'est ni acheté ni fabriqué mais conçu par des professionnels qualifiés.

Nous envoyons 1-2 ingénieurs pour l'atelier de montage chez le client, pour l'installation, la mise en service et les instructions aux opérateurs. Nous offrons une assistance après-vente tout au long de la durée de vie de la machine. Nous resterons à vos côtés pour la machine d'extraction de film avant et pendant la période de garantie, et fournirons des services.

Nous sommes un fabricant réputé de machines d'extraction de film avec plus de 18 ans d'expérience dans la conception et la fabrication. Nous produisons principalement des machines à films géomembranes, des machines à films pour serres, des machines à films de paillage et des machines à films d'emballage. Nous avons servi plus de 200 clients et espérons vous offrir un produit de haute qualité et un bon service.

Un centre R&D composé d'ingénieurs ayant plus de 20 ans d'expérience en R&D de machines d'extraction de film répond positivement à chaque demande pour concevoir des machines qui répondent aux exigences particulières des clients. Nous faisons tout ce qui est en notre pouvoir pour fournir le meilleur équipement en plastique à chaque client.