Brand: XINFU

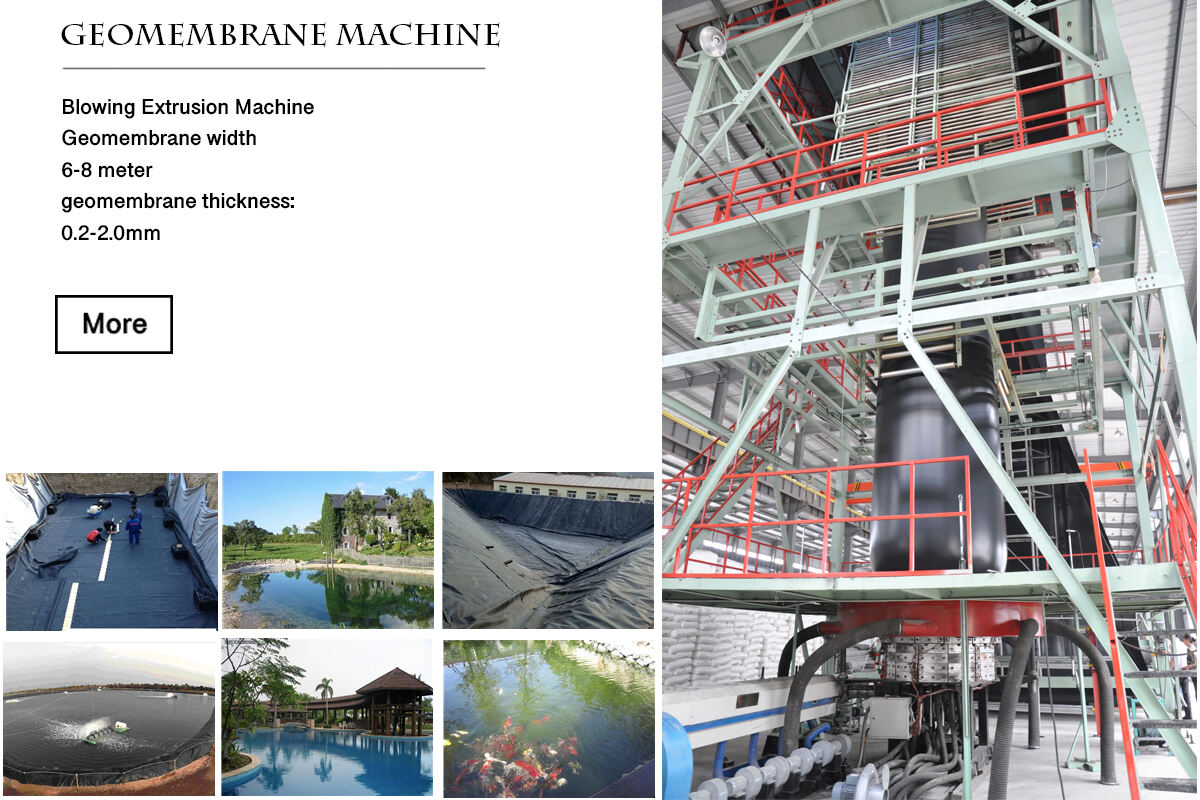

XINFU is proud to introduce our 3 layer 8 meter HDPE film extrusion blowing machine waterproof geomembrane making machine is created particularly for the manufacturing of waterproof geomembranes. The unit are manufactured to your highest requirements quality is using is top and technology this is certainly modern make sure that our customers produce excellent products and services.

Our 3 layer 8 meter HDPE film extrusion blowing machine waterproof geomembrane making machine device is ideal and could be trusted towards the construction industry to be a layer is protective landfills, reservoirs, ponds and canals. The unit was made to create films with a thickness including 0.5 mm to 3 mm and width of up to 8 meters, which is well suited for major productions.

The apparatus makes utilization of polyethylene is high-density this product this is certainly natural can perform producing geomembranes that might be really resistant to water permeation, UV chemical and light compounds. It shall help make certain that your product or service is durable, long-lasting and may withstand climate harsh. The 3 layer 8 meter HDPE film extrusion blowing machine waterproof geomembrane making machine device process shows that the item is versatile, elastic and can conform to the contours through the land or framework, providing a lasting and seal protected.

The system comes insurance firms a cutting-edge control system that ensures accurate and dimensions that are precise the production that is entire is entire. Our technology enables production is high-speed compromising on quality. The apparatus is easy to work well with and therefore might be controlled through an interface is user-friendly.

XINFU’s 3 layer 8 meter HDPE film extrusion blowing machine waterproof geomembrane making machine just a zero-maintenance and energy-efficient option, which lowers the production expense generally speaking. The apparatus is developed to perform at a noise this is certainly decreased, ensuring a secure and environment that is comfortable working.

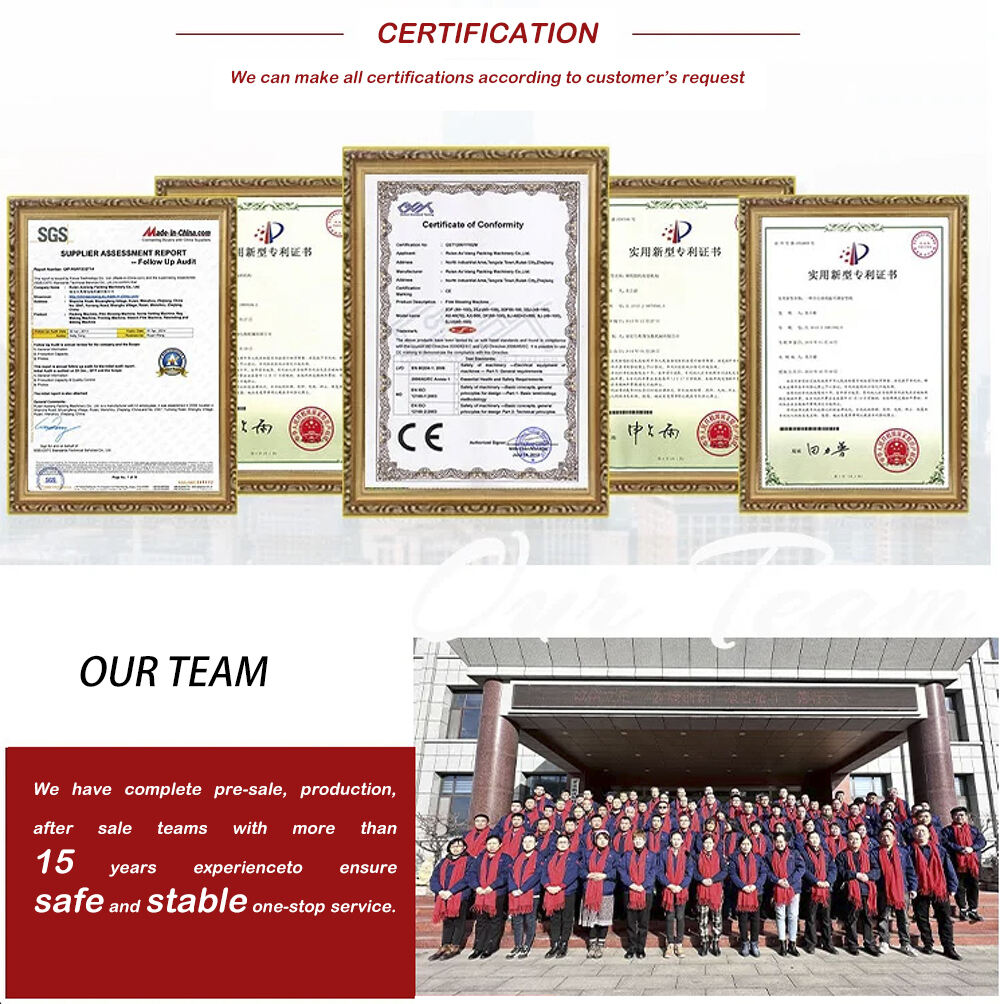

Our professionals are taught to provide after-sales that are comprehensive into the consumers, ensuring our devices continue to run at maximized performance levels. This consist of upkeep regular, prompt support this is certainly technical training for the customers’ manufacturing staff.

Model | 3FM6500 | 3FM7500 | 3FM8500 | 3FM10500 | |||

Raw material | HDPE, LDPE, LLDPE | ||||||

Geomembrane width | 6 meter | 7 meter | 8 meter | 10 meter | |||

Geomembrane thickness | 0.3-2mm | 0.3-1mm | |||||

Max. output | 1000KG/H | 1200KG/H | 1500KG/H | 1500KG/H | |||

Extruder | 150*1+135*2 | 180*1+150*2 | 180*3 | 180*3 | |||

Die head | 1700mm | 2000mm | 2200mm | 2200mm | |||

Line speed | 0-10m/min | ||||||

Total power | 1000KW | 1200KW | 1500KW | 1500KW | |||

Dimension | 18*8*21 meter | 19*9*23 meter | 20*10*25 meter | 22*11.5*28.5 meter | |||

Film to produce | ||||||

Film width: | Film thickness: | |||||

Film layers: | Film application: | |||||

Electricity | ||||||

Three phase: | V | Frequency: | Hz | |||

Single phase: | V | Neutral line: | Must have. | |||

Contact information | ||||||

Company name | Website: | |||||

Contact person | Position: | |||||

Phone number | Email: | |||||

/images/pro-inquiry-bg.jpg)

Our friendly team would love to hear from you!