You would think that plastic film packaging was made how? It's quite fascinating! These plastic films are made through the process of blown film extrusion and manufactured using a machine known as blown film extruder. XINFU abc film blowing machine to better understand a blown film extruder, its benefits and working procedure along with some precautions to keep in mind we must start briefing on what actually is this machinery and where all it can be used!

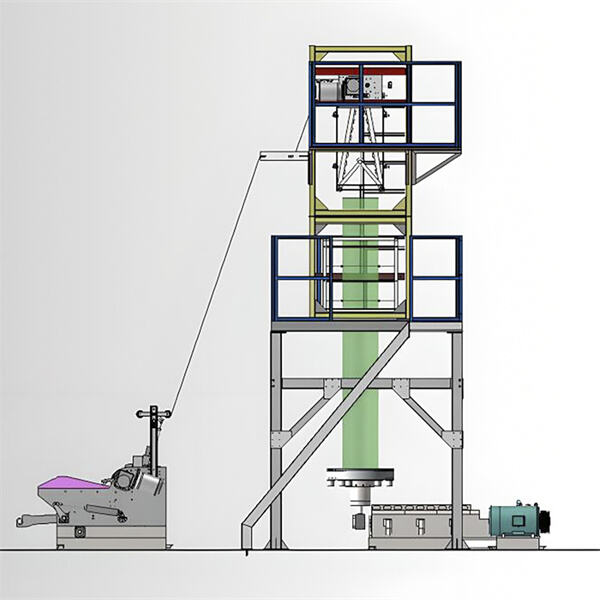

A blown film extruder is a machine that creates thin films from plastic material. These work by melting the plastic pellets and air passing them through a die to form as tube. XINFU blow extrusion machine this tube is then inflated using compressed air to stretch it into a film. There are countless advantages to using a blown film extruder. It enables manufacturers to fabricate custom sized plastic films for numerous applications, first and foremost. It also guarantees uniform thickness over excellence of the entire film. Blown film extrusion is faster than other methods of producing the same type and size film without waste.

With technology development, the blown film extrusion machines have also developed. Modern versions have sensors and software that track and control temperature, pressure; film thickness. XINFU blow film extrusion machine this technology boosts the efficiency, quality and safety during manufacturing. Just like with all other types of industrial machinery, there are risks from the blown film extruder to those workers who operate it. Hid is important to wear protective gears as gloves and safety glasses, earplugs too. The machine is only handled by trained operators, who follow strict safety protocols during operation and when servicing the machine. Always make sure to turn off the machine before performing any maintenance work.

Proper installation and operation are required for the efficient running of blown film extruder. Operators need to verify that the right kind of plastic pellets are used and make sure the machine is set up properly so you can keep it at a certain temperature, pressure and thickness. Frequent checks of both the machine and film quality during production. XINFU blowing film machine when producing plastic films, regular maintenance and quality control is essential as using alarming materials or failing to clean the dies promptly can affect both processing conditions and film quality. Maintenance tasks involve checking for wear and replacing typical elements, cleaning the machine as required or directed. (Refer to Operator's Manual), and lubricating any moving parts on a daily basis. The control of the quality such as film thickness, width and it requires testing them for durability, clarity also to know about their tensile strength.

Blown Film Extruder: The blown film extruders are used in blowing the plastic films that find wide usage. XINFU blown extrusion process that includes special made packaging solutions like bags, pouches and wraps for your food or nonfood products. The method is also applied to manufacture industrial films related construction, agriculture and medicinal usages. In other words, custom films are produced in order to satisfy particular client needs.

We send 2 engineers workshop customer guarantee installation, blown film extruder machines purchased customers operator's training. offer after-sales assistance throughout life machine, we keep touch you after during guarantee, provide you service.

blown film extruder an RD centre engineers 20 years RD experience. one your request get enthusiastic response. can create machine meets customer's specific requirements. In spirit management, highest quality gets customers, great service key winning customers every effort create most effective plastic equipment every customer.

We're a leading maker of film blowing machines with 18+ years manufacturing and design experience. We produce geomembrane, mulching, packaging, and greenhouse film blowing machines. We've served more blown film extruder 200 clients and hope to provide you with the highest quality of products and outstanding service.

company currently 2 office buildings research centre, seven blown film extruder, more 100 employees. majority them been industry than 10 years, a wealth experience exceptional expertise. have comprehensive independent production process ensures each component your equipment designed experts.