A blown film extrusion is a kind of plastic bag making process, where these machines are known as the clutch foil. XINFU blow film extrusion machine are vital elements to the everyday items that we come across, be it when wrapping groceries or for tamper resistant sealing of others. This blog post will take an in-depth dive into the amazing universe of blow film extrusion - looking at some features and benefits, as well discussing its innovative history within plastic film manufacturing.

Introduction to Blown Film Extrusion; Benefits of blown film extrusion

Blown film extrusion has as one of its passes efficiently and sustainability. This method is different than other methods because it requires less energy and keeps up the productivity at high levels. Actually, it will lay down a pretty impressive 100 feet of plastic film in one minute. Also, the inherent versatility in this method enables production of plastic films with variety gauges and sizes that suit a broad spectrum from shopping bags to packaging covers.

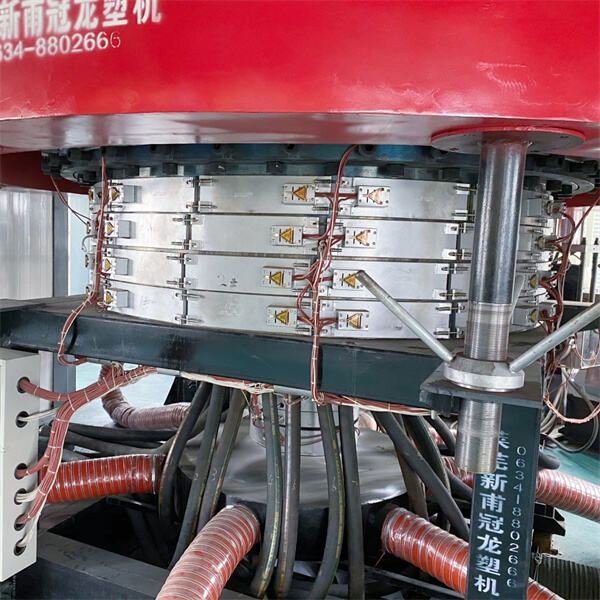

Blown film extrusion: Over the decades, blown Film Extrusion has seen a lot of development through continuous technology upgradation within this industry. XINFU blown extrusion process come with in-built bubble cooling system providing even thickness and consistently producing high quality plastic film end to end.

Blown Film Extrusion machines are an example of operating such highly hazardous machinery. Without proper training and experience, the hazards of an excavator can be even greater than a simple earth mover - advanced operators will follow safety practices cautiously with such serious machinery. Furthermore, these devices come with control systems that detect and shut down automatically when they sense any hazards to offer safe working conditions.

What is Blown Film Extrusion Process?

Blown film extrusion machines are made in such a way that they can be easily operated. So, I am making this easy by breaking it down into simple steps:

Step 1: Load plastic resin pellets into the machine hopper to melt them down as a liquid.

The tube of course is molded from the round pellets melted and pressed through a die.

Fill the tube with air to form bubble.

Allow the bubble to cool and cut it into your ideal size for future use.

Like other blown film extrusion machines, properly maintaining your XINFU blown film extrusion machine is essential for getting the best performance and output quality. Ensure you adhere fully to manufacturer maintenance guidelines, be it changing screws and barrels or replacing filters. Quality control procedures are also implemented to ensure that the plastic films conform to certain specifications in relation to thickness, width and clarity as requested by customers.

will send couple engineers workshop customer blown film extrusion installation running customer's machines operator's training. provide after-sales service along lifetime machine. will in contact you during after warranty provide service.

company now home two office buildings research blown film extrusion, seven workshops over 100 employees. are employed area more 10 years experienced talent exceptional skills. We an extensive independent production system, makes sure every component equipment produced experts.

blown film extrusion professional manufacturer film blowing machine 18 years manufacturing design experience. specialize producing geomembrane blowing machine, greenhouse film blowing machine mulching blowing machine packaging film blowing machines. served than 200 clients hope deliver top-quality product great service you.

With RD Centre blown film extrusion 20 years RD expertise, we'll able respond promptly every demand create machines meet customers' particular requirements. work hard provide finest plastic machines every customer.