If you are looking for a method of fabricating superior safe products Blown Extrusion acts as the best solutions. This new technology allows you to create hollow items with a range of layer thicknesses making it ideal for producing anything from water bottles to plastic jars. This article will look at the benefits of XINFU blown extrusion process, how it works and exactly how you should be using this to improve or maintain your own product quality.

Blown Extrusion is best-known for its ability to create products using high degree of consistency which make it the most desirable in a global scale. Its consistency can be readily translated into reliability of products, as they all will demonstrate the same behavior which meets the specifications. XINFU blown film extruder is an incredibly capable process. It takes less material, time and power compared to other production methods. It makes it a cost-effective choice for manufacturers, and this savings in raw materials and manufacturing costs.

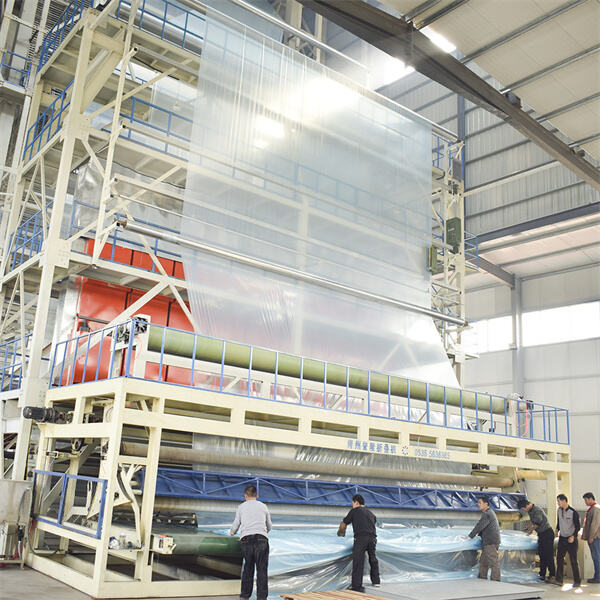

Some machines offer multiple heads so you can produce a number of different shaped products and styles. The best part about this is that you can create one-of-a-kind products for the customers, which helps you stay ahead in market. Innovative extruders will have the ability to help you monitor and control throughout the process in real-time; adapting as needed via sensors that modify temperature speed or pressure. Having this level of control means that each XINFU blown film extruder machine run produces products adhering to the same rigorous standards as our published results and safety.

It produces commodities with uniform breadth levels, most likely one of its very hefty advantages. For goods like drinking water containers, clean breadth is crucial in maintaining them sound also safe. You can create services and products are resistant to effect, heat and chemical compounds. The blown film extrusion is applicable in both consumer and commercial usage. They are less likely to rupture or seep which is a crucial characteristic for open products and solutions subjected to force or tension. Blown Extrusion gives you the ideal products for strength and durability over a number of other manufacturing methods.

How to Implement Blown Extrusion in Your Manufacturing Process

There are some very basic steps you will need to follow before getting on the work with your Blown Extrusion machine. The raw materials such as synthetic pellets are loaded to the machine. The gear will melt the pellets then and press them through a die, which could give it its shape as well thickness. In the end, this will be cut and cooled to their specific dimensions.

To make certain your Blown Extrusion machine provide you with consistent uptime maximum it is essential to keep well serviced and maintained. This can involve regular attributed inspections of the machine, cleaning its components as well as replacing all worn or damaged parts. Regular maintenance of blown film extrusion line will help you to produce high-quality items.

We a Blown extrusion maker blowing machines film over 18 years manufacturing design expertise. make geomembrane mulching, packaging greenhouse film blowing machines. have served over 200 clients, we look forward providing with highest quality products excellent service.

We send Blown extrusion engineers workshop customer install, operate training operators. provide after-sales service along lifespan machine. will stay touch you throughout after warranty provide support.

Blown extrusion now 2 offices, research center, 7 workshops, over 100 employees employed business. majority our staff been working industry more10 years highly skilled specialists years knowledge. production process independent complete, ensuring every component equipment you purchase made experts.

We an Blown extrusion center engineers have than 20 years RD experience, each your requirements met positive responses create machine meets customer's particular requirements. We'll everything can supply most efficient plastic machines possible each customer.